Dissolved Air Flotation Technology: An Efficient Solution in Water Treatment

Dissolved Air Flotation (DAF) is an advanced technology widely used in water treatment and wastewater purification. By using tiny bubbles to separate suspended particles, grease and other pollutants from water, DAF technology has become an important tool for industrial, municipal and agricultural wastewater treatment due to its high efficiency, reliability and environmental friendliness.

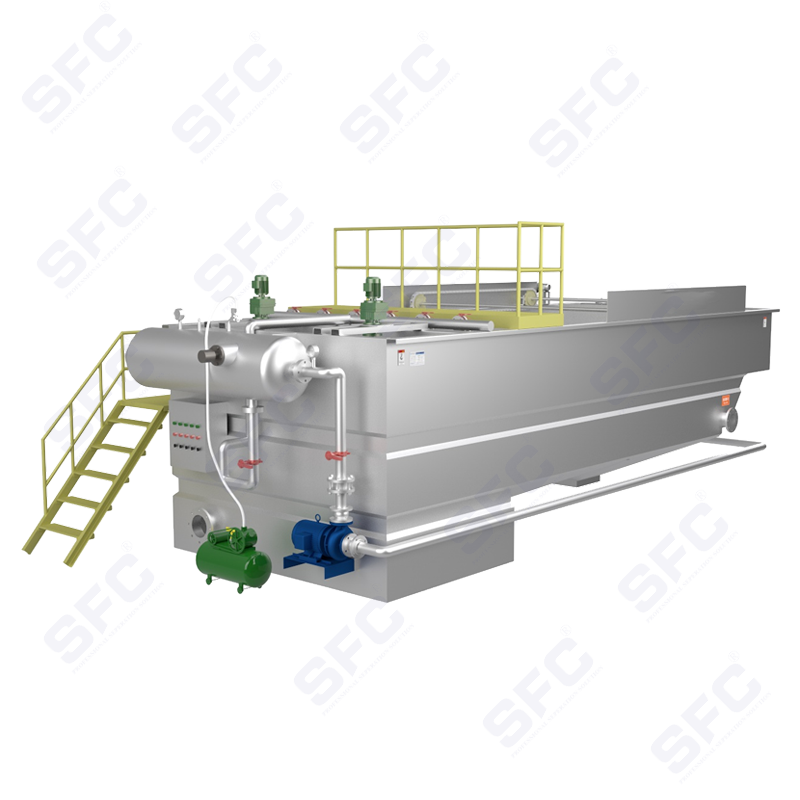

Dissolved Air Flotation System usually includes the following key parts:

Pressurized Dissolved Air System: Dissolve air in water to form supersaturated dissolved air water.

Release Device: Release dissolved air water under reduced pressure to produce a large number of tiny bubbles.

Reaction Tank: Used to mix sewage and dissolved air water and promote the combination of bubbles and pollutants.

Scum Collection System: Used to remove floating pollutants.

Main Features of Dissolved Air Flotation

High Efficiency Separation

DAF technology can quickly remove suspended matter, emulsified oil and colloidal substances in water, and is particularly suitable for treating wastewater containing high concentrations of pollutants. Compared with traditional sedimentation methods, DAF has faster separation speed and higher efficiency.

Wide range of applications

Dissolved air flotation is suitable for a variety of wastewater treatment types, including industrial wastewater, municipal sewage, food processing wastewater, and oily wastewater. Its flexibility makes it an ideal choice for cross-industry water treatment.

Small footprint

The DAF system has a compact structure and a small equipment size, making it suitable for installation in places with limited space. This is especially important for urban sewage treatment plants or small industrial enterprises.

Low operating cost

The dissolved air flotation system has low energy consumption, simple maintenance, and relatively low long-term operating costs. In addition, the recovered scum can also be recycled to further reduce treatment costs.

Excellent environmental performance

DAF technology is environmentally friendly and can effectively reduce the content of pollutants in water bodies, meeting strict environmental regulations. At the same time, it does not introduce additional chemicals, avoiding the risk of secondary pollution.

How dissolved air flotation works

The core of dissolved air flotation lies in the generation of bubbles and the capture of pollutants. The specific steps are as follows:

Pressure dissolved air

Under high pressure conditions, air is dissolved in the returning clean water to form supersaturated dissolved air water.

Bubble release

After the dissolved air water is injected into the reaction tank, a large number of micron-sized bubbles are released by decompression. These bubbles have a large specific surface area and can efficiently adsorb pollutants.

Bubble attachment

The tiny bubbles combine with suspended particles or grease in the water to form a complex with low density.

Floatation separation

The complex floats to the surface of the water with the bubbles, forming a scum layer, which is then removed by the scraper. The purified water is discharged from the bottom.

Application areas of dissolved air flotation

Industrial wastewater treatment

In the papermaking, textile, chemical, food processing and other industries, DAF technology is widely used to remove suspended matter, grease and organic matter from wastewater. For example, in food processing plants, DAF can effectively separate fat and protein from dairy wastewater.

Municipal sewage treatment

Municipal sewage treatment plants use DAF technology to remove suspended particles and grease from sewage, providing pretreatment support for subsequent biological treatment processes.

Oily wastewater treatment

In oil extraction, refineries and shipping industries, DAF technology can efficiently separate emulsified oil and suspended matter from oily wastewater to meet strict emission standards.

Drinking water purification

DAF technology can also be used for drinking water treatment, especially to remove algae, suspended particles and trace pollutants in water to ensure water supply safety.

Agriculture and aquaculture

In the fields of agricultural irrigation and aquaculture, DAF technology is used to purify aquaculture wastewater, reduce eutrophication problems, and improve the recycling rate of water resources.

Future development trend of dissolved air flotation

With the global attention to water resource protection and sustainable development, dissolved air flotation technology is moving towards a more intelligent and energy-saving direction:

Intelligent control

With the help of sensors and automatic control systems, future DAF equipment can monitor water quality parameters in real time and automatically adjust operating parameters to optimize treatment effects.

Green technology innovation

The application of new materials and energy-saving technologies will further reduce the energy consumption and carbon emissions of DAF systems, and promote them to move towards green water treatment technology.

Modular design

The modular design makes DAF equipment more flexible and easy to customize according to different scales and needs, especially suitable for small and medium-sized enterprises.

Resource utilization

The recovered scum can be converted into valuable by-products such as biofertilizer or energy raw materials through further processing to maximize the utilization of resources.

Dissolved air flotation technology has become one of the important pillars of modern water treatment due to its high efficiency, flexibility and environmental friendliness. Whether in industrial wastewater treatment, municipal sewage treatment or special application scenarios, DAF technology has demonstrated excellent performance and wide application potential. In the future, with the continuous advancement of technology and the increase in environmental protection needs, dissolved air flotation will continue to contribute to the sustainable management of global water resources and create a cleaner and healthier water environment for human society.

English

English Español

Español